Thermal Measurements for SUPLET Board Mounted Power Modules

time:02,08,2019

Contens

Description

This document describes the thermal test method and thermal design considerations in the application system with sealed enclosure. In the closed environment, due to the shortage of air flow, the BMP is conduction cooled via its aluminum baseplate contacting closely with the system enclosure, thus ensuring the BMP to operate within the normal temperature range.

To verify the thermal characters of the BMP in the sealed box application, a big size heat sink (cold wall) is often used to simulate the various system chassis, and a thermal isolating box is often used to simulate the sealed box and control the ambient temperature and cold wall temperature similar with the application environment.

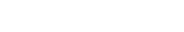

Typical RFPA Application

Application example: RFPA in wireless communication, shown as below,

Both the RF functional amplification transistor and the thermal baseplate of BMP module shall contact with the system enclosure closely. The joint shall be filled with qualified thermal gap filler, and the heat shall transmit to exterior of the sealed box in time to make sure the RFPA operates within the normal temperature range.

Thermal Measurement method

The sealed box cooling conditions are different since both ambient temperature (inside the sealed box) and the baseplate temperature are important. In addition, thermal radiation from the module can be a significant part of the heat transfer. The thermal measurements should be performed at temperatures close to the actual operating conditions.

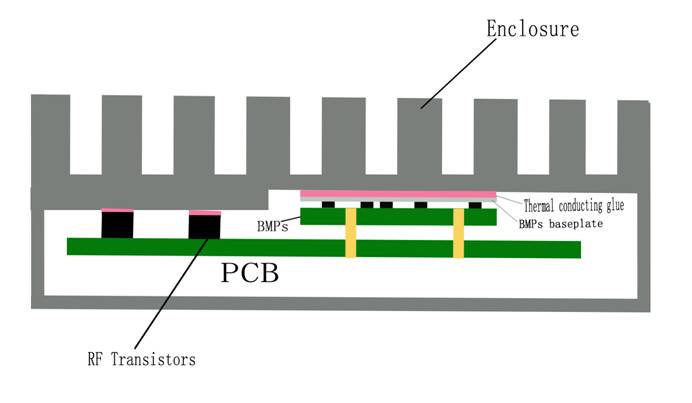

The setup below is suggested for thermal verification. It is important that the BMP under test is adequately attached to the cold wall (in a similar way as it intended to be in its application). The hood and the cold wall should preferably be individually temperature controlled both adding and removing heat, in order to control the air temperature inside the box and baseplate temperature of the BMP.

Key points of verification test

1. Test board: a test board with necessary components and test circuit that makes the BMP operates normally.

2. BMP: board mounted power module to be verified.

3. BMP baseplate: thermal baseplate of board mounted power module

4. Thermal conductive gap filler: the gel used to fill thermal-conduction gaps. The thermal conductive rate and thickness of the gap filler must be considered to ensure the delta T between the BMP baseplate and heat sink within acceptable level.

5. Heater: some resistors can be used as heater help to raise the temperature of the heat sink.

6. Heat Sink:Recommended dimension:360*200*70mm

7. Tref in the datasheet: Temperature test point of the baseplate or key components, refer to the datasheet.

8. Thermal isolating box: a thermal isolating box is used to shield the air flow of test environment and help to control the ambient temperature of the BMP under test.

9. Location for ambient temperature sensor.

10. Chamber with high/low temperature control function, the size of chamber must contain the sealed box test setup.

Recommended test method:

After fixed the above test setup into the temperature chamber, stick thermocouple sensor at the Tref defined in the datasheet of key components or on the baseplate, at least one thermocouple sensor is placed on the heat sink near the BMP to test the temperature of heat sink, and one thermocouple sensor is placed at location defined in the datasheet to test the ambient temperature in the sealed box. Heater resistors driven by the external power is used to warm up the heat sink and help to reach thermal steady state or trigger OTP easier. Then record the temperature datas of thermal steady state to at the moment of OTP.

Conclusion

Standard wind tunnel measurements of thermal properties of power converters like the output current derating curve are not suitable for sealed box applications. The sealed box cooling conditions are different since both ambient temperature (inside the sealed box) and the baseplate temperature are important. In addition, thermal radiation from the module can be a significant part of the heat transfer. The thermal measurements should be performed at temperatures close to the actual operating conditions.